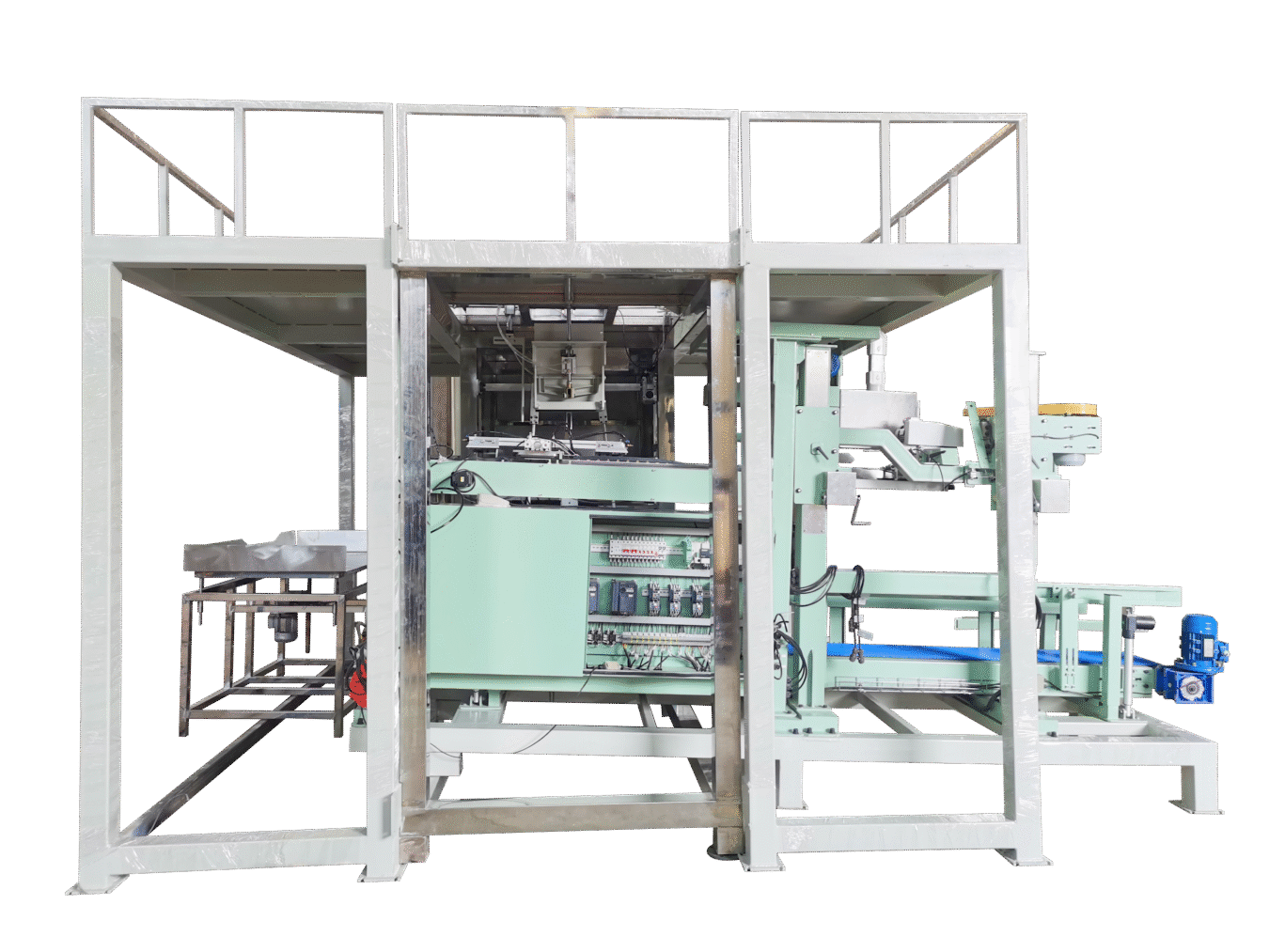

Automatic packaging machines have become the backbone of industrial production, driving efficiency and consistency across sectors. This analysis explores their critical role in contemporary manufacturing, highlighting cost-benefit advantages and sector-specific applications while adhering to global operational standards.

Core Advantages of Automatic Packaging Systems

1. Unmatched Production Efficiency

- Speed: Processes 80–150 units/minute, 3–5x faster than manual methods.

- Labor savings: 1 system replaces 6–8 workers, reducing annual labor costs by $200,000+.

- Case study: A dairy producer cut packaging time per batch from 3 hours to 45 minutes.

2. Precision & Quality Control

- Weight accuracy: ±0.5% tolerance for 0.5–50 lb (0.2–22.7 kg) packages.

- Seal integrity: Heat-sealed closures withstand 3–5 PSI (0.2–0.34 bar) pressure tests.

- Vision systems: Detect defects like mislabels or leaks at 120+ inspections/minute.

3. Cost-Effective Scalability

| Metric | Manual Process | Automated System |

|---|---|---|

| Material waste | 8–12% | <1% |

| Energy consumption | 30–35 kW/h | 22–25 kW/h (VFD optimized) |

| Downtime | 15–20 hours/month | <5 hours/month |

Industry-Specific Applications

1. Food & Beverage

- Hygiene compliance: CIP (Clean-in-Place) systems meet USDA/FDA standards.

- Adaptability: Handles granular sugar to oily snacks without cross-contamination.

2. Pharmaceuticals

- GMP adherence: Nitrogen-flushed packaging extends drug shelf life by 30–40%.

- Traceability: Laser coding ensures compliance with DSCSA serialization rules.

3. Cosmetics

- Aesthetic precision: Fill ±0.1 oz (3 ml) creams into custom-shaped containers.

- Premium finishes: Glossy seals and tamper-evident features enhance brand appeal.

Strategic Implementation Guide

1. Choosing the Right System

- Entry-level: $50,000–$120,000 (30–60 units/minute, basic automation).

- Mid-range: $130,000–$250,000 (IoT-ready, 80–150 units/minute).

- High-end: $300,000+ (pharma-grade, 200+ units/minute).

Chinese manufacturers deliver 25–40% cost savings versus European counterparts with 4–6 week lead times.

2. Maintenance Best Practices

- Daily: Clean sensors, verify emergency stops (<0.5s response).

- Weekly: Lubricate chains with ISO VG 220 oil.

- Monthly: Recalibrate load cells using 50 lb (22.7 kg) test weights.

3. Future-Proofing Investments

- AI integration: Machine learning optimizes sealing parameters for new materials.

- Modular upgrades: Add robotic palletizers or vision inspection post-purchase.

- Sustainability: Solar-compatible models reduce grid dependence by 20–25%.

Why Modern Manufacturers Prioritize Automation

- Regulatory compliance: Meet FSMA, EU MDR, and ISO 22000 effortlessly.

- Market agility: Switch packaging formats in <10 minutes for seasonal SKUs.

- ROI certainty: Most users recover costs in 12–18 months via waste reduction and labor savings.

Leave a Comment

Your email address will not be published. Required fields are marked *