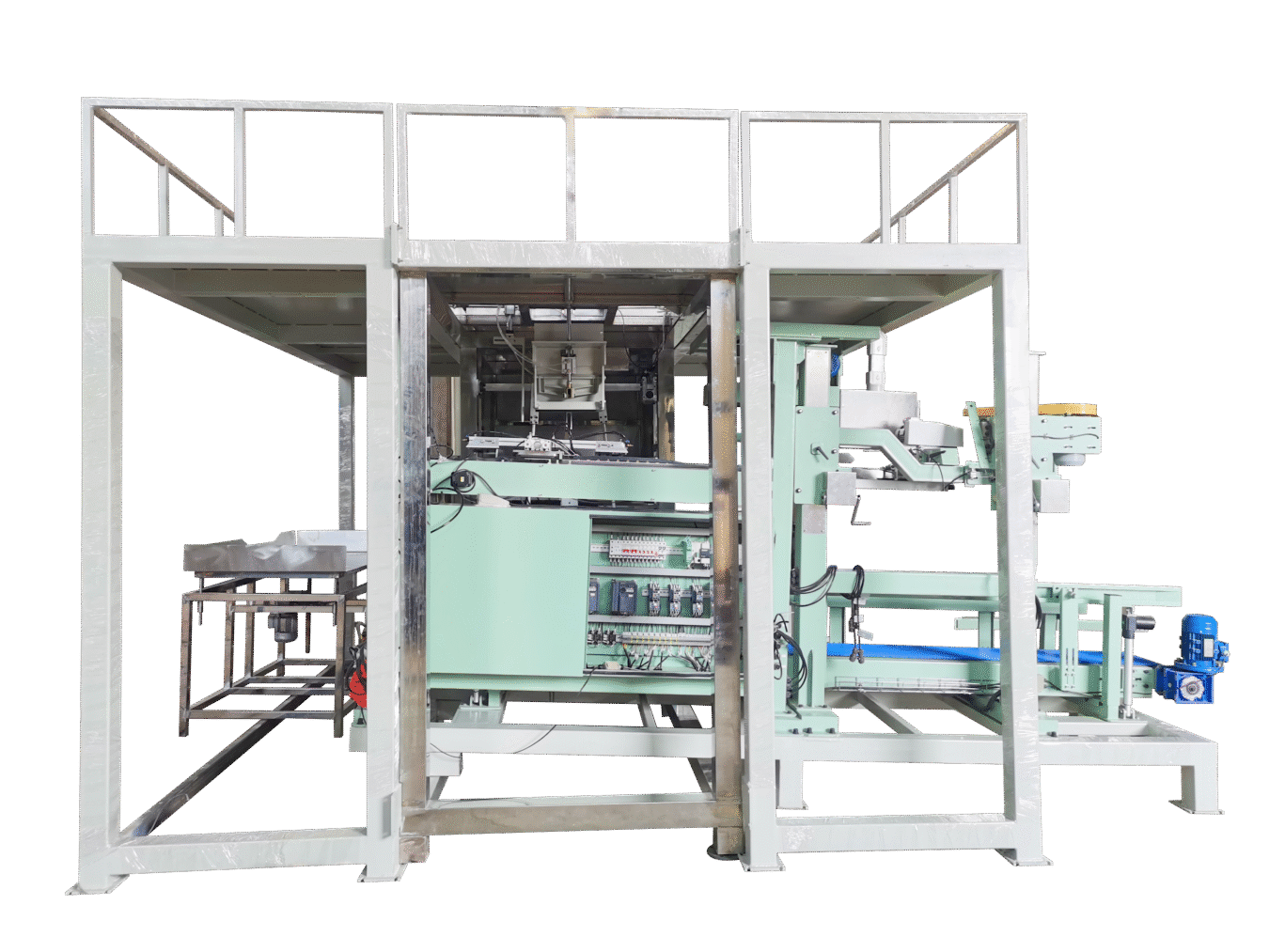

The price of a fully automatic packaging machine is influenced by factors such as level of automation, production capacity, and configuration. To reduce the failure rate of the machine, the following measures can be implemented:

Key Measures to Reduce Failure Rate:

- Regular maintenance and inspection: Develop a detailed maintenance plan and perform periodic checks, including cleaning, lubrication, and tightening loose parts, to prevent potential issues.

- Training for operators: Strengthen operator training to ensure familiarity with operating procedures and correct machine usage, avoiding failures caused by improper operation.

- Quality control: Choose high-quality machines and components to ensure reliability and minimize failures due to manufacturing defects.

- Monitoring and alarm systems: Install monitoring systems to track machine operation in real time and trigger alerts when abnormalities are detected, enabling timely intervention.

- Parameter optimization: Adjust machine settings appropriately based on packaging materials and product characteristics to maintain optimal performance.

- Failure analysis and documentation: Conduct detailed analysis when failures occur, record causes and solutions, and use this information for future prevention and faster troubleshooting.

By implementing these measures, companies can effectively reduce the failure rate of fully automatic packaging machines, improve production efficiency and product quality, minimize downtime, and enhance overall competitiveness.

For specific pricing or technical support related to fully automatic packaging machines, please feel free to contact our professional team for customized solutions.

Leave a Comment

Your email address will not be published. Required fields are marked *