BB fertilizer production line

The BB fertilizer production line is a kind of equipment that takes chicken and pig manure as the main raw materials, adds a certain amount of nitrogen fertilizer, phosphorus fertilizer, potassium fertilizer, magnesium sulfate, ferrous sulfate and other substances, and ferments rice bran, yeast, soybean meal and sugar for a certain period of time as biological bacteria. Under the action of sulfuric acid, it is mixed and fermented to produce biological fertilizer

Compound fertilizer production line

The process flow of a compound fertilizer production line can generally be divided into: raw material batching, raw material mixing, raw material granulation, granule drying, granule cooling, granule classification, finished product coating, and finally finished product packaging.

De-icing agent production line

The deicing agent production line includes: batching system, conveyor, batching system frame, drum mixer, ton bag machine, quantitative packaging machine, silo and other equipment.

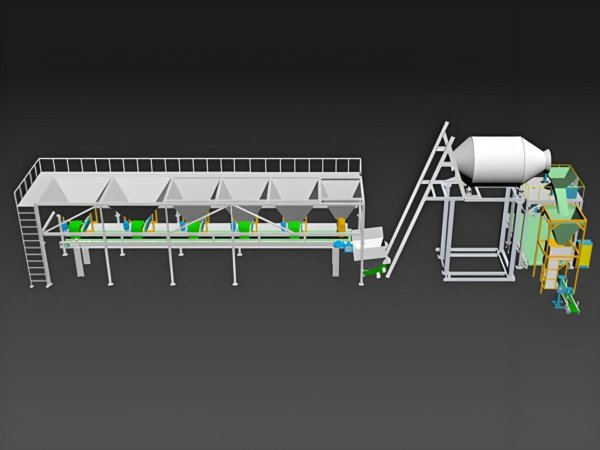

Dynamic batching system

The dynamic batching system integrates multiple equipment such as raw material storage, transportation, weighing and batching, dust removal, material mixing, packaging and filling.

Intelligent fertilizer blending machine

The FLD2016 intelligent soil improvement and fertilization machine, a soil improvement and fertilization wonder tool, mixes nitrogen, phosphorus and potassium fertilizers according to expert formulas and then dry-mixes them by physical methods to produce blended fertilizers.

Organic fertilizer production line

The products produced by the organic fertilizer production line are made from fresh chicken and pig manure as raw materials, without any chemical components. Chickens and pigs have poor digestive capabilities and can only consume 25% of the nutrients in the feed, while the remaining 75% of the nutrients in the feed are excreted with the manure. As a result, the dry finished products contain nitrogen, phosphorus, potassium, organic matter, amino acids, proteins and other components.

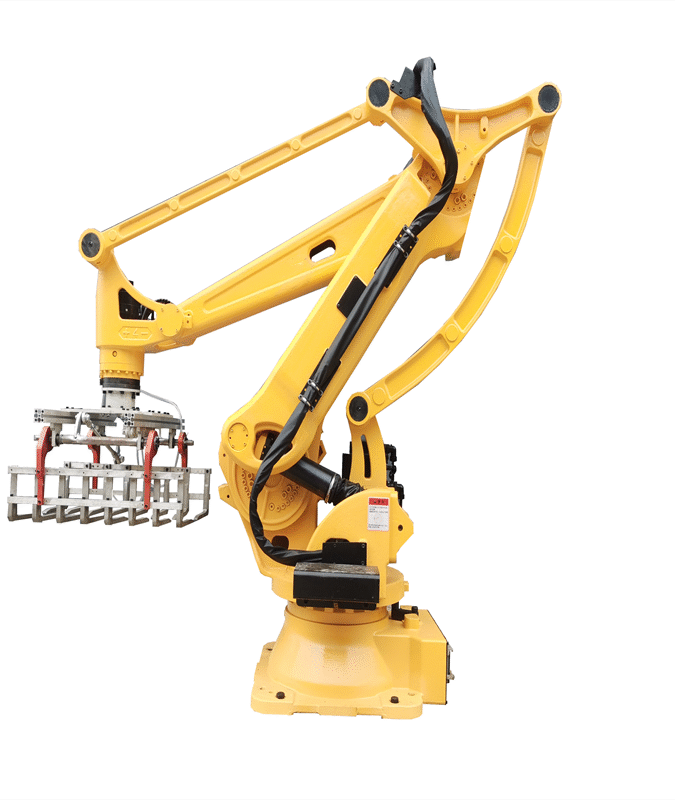

Palletizing robot

The palletizing robot integrates multiple industry-specific process packages, combined with soft PLCS and various bus interfaces, to help customers easily handle various process challenges. The high-rigidity structure, combined with the high-speed intelligent palletizing process package, increases efficiency by 20%, helping customers complete their work quickly, effectively and economically.

Scraper conveyor

Scraper conveyors are used in grain warehouses, docks, grain processing plants, light industry and pharmaceuticals, brewing and other industries to transport various raw materials, semi-finished grains, feeds and other small granular or powdered materials.

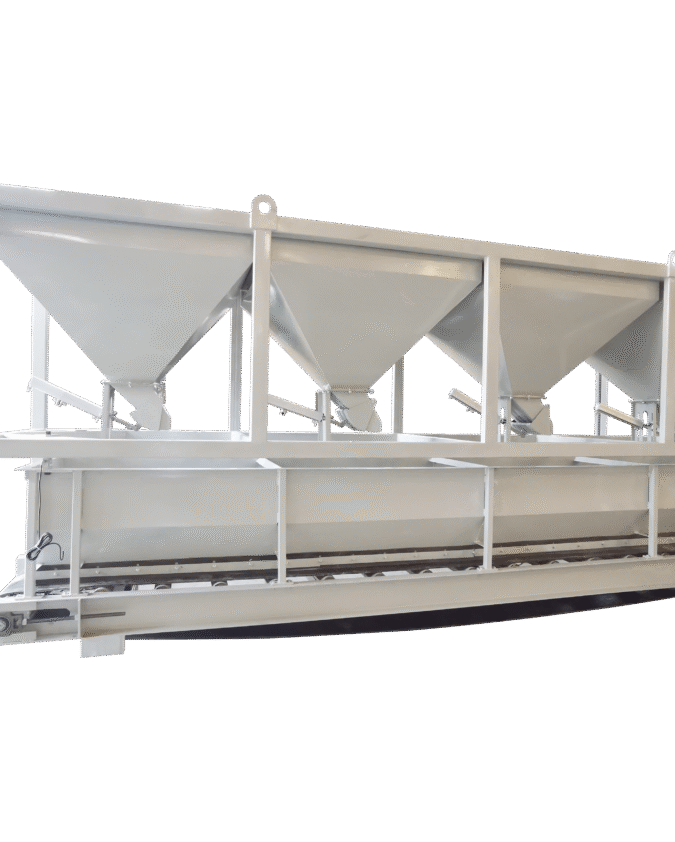

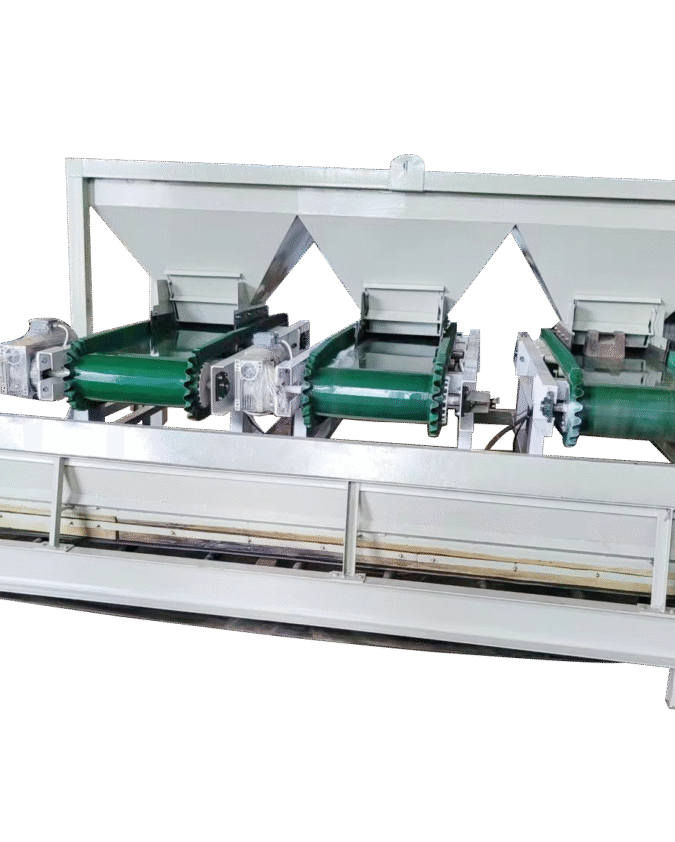

Static batching system

The static batching system integrates feeding, weighing, unloading and conveying. Applicable materials and scenarios: Powdered and granular materials, such as organic fertilizers, compound fertilizers, cement and fly ash, etc., are applied in agricultural production, feed processing and other industries.

TDTG series bucket elevators

The TDTG series bucket elevators adopt strong bucket belts or polyester nylon bucket belts, which have low elongation and are durable and reliable. The head wheel adopts a refined rubber wheel, which is fireproof and wear-resistant, effectively preventing the belt from slipping.

TLSS series screw conveyor

The TLSS series screw conveyor can be widely applied in horizontal and inclined (with an inclination Angle less than 15.) Vertical conveying of various powdery, granular and small block materials, such as: bean 柏, flour, bulk grain, etc.

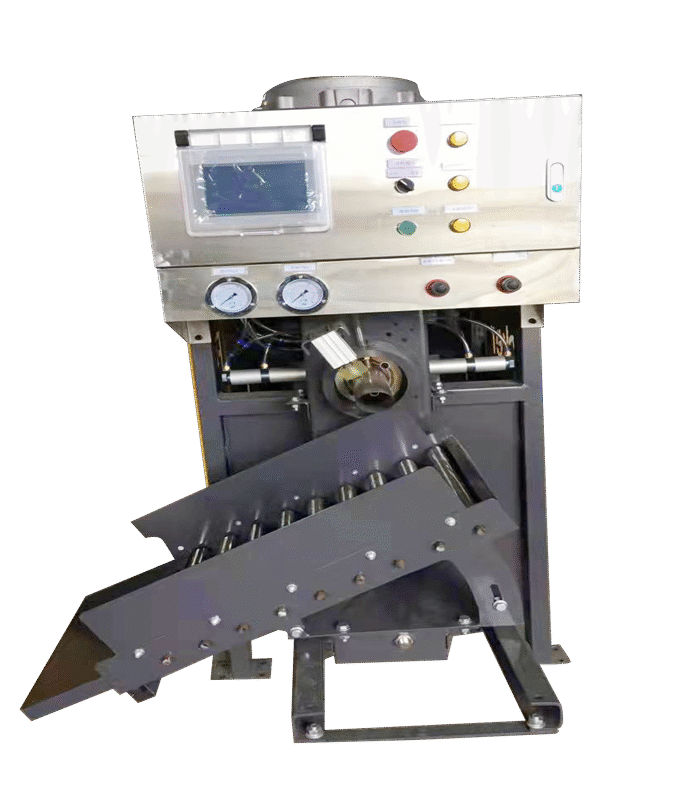

Valve bag packaging machine

The valve bag packaging machine, also known as the valve mouth machine, is mainly used for valve bag packaging of powder materials with a mesh size of 325-2500. It can automatically complete the functions of bag pressing, filling, sealing, bag dropping and gate closing. It only requires manual insertion of the valve bag. The operation is simple and the performance is stable.

Water-soluble fertilizer production line

The water-soluble fertilizer production line has a complete set of strict operation procedures and systematic management methods. The use of equipment and technology has increased work efficiency by 10% to 25% compared with products in the same industry. The quality of the finished products is matched with multiple production processes and formulas, all reaching or even exceeding the prescribed standards.

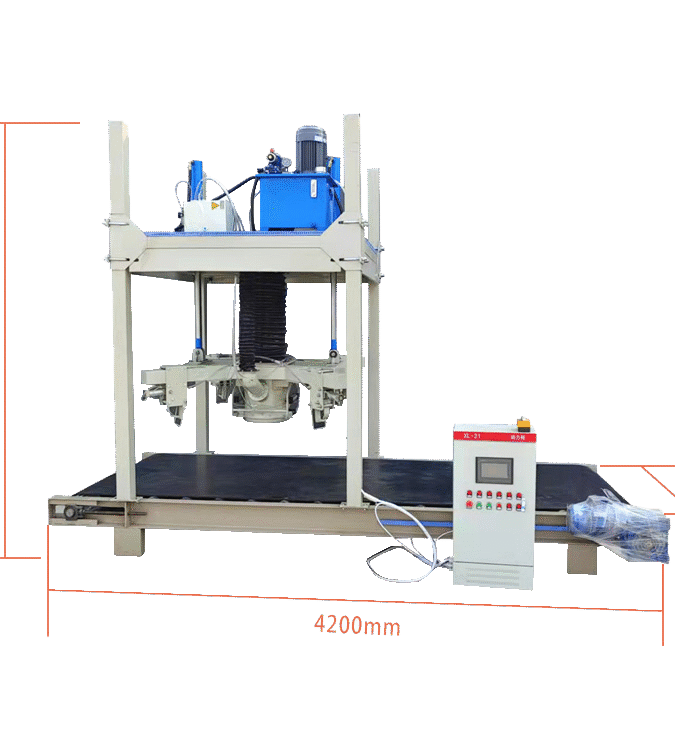

YH-1000G granular ton bag packaging machine

The YH-1000G granular ton bag packaging machine adopts arc-shaped doors and three-stage feeding, which can adapt to the flow rates of various materials. Fast packaging speed, high precision, low overall height, small space occupation and simple maintenance. Optional and reserved dust removal systems can be used for the system to recover granular materials.

YH-1000P powder ton bag packaging machine

The YH-1000P powder ton bag packaging machine is suitable for ultra-dry powder, cement, dry powder mortar, alumina powder and other powder materials, as well as industries such as feed, flour, water-soluble fertilizer, additives, chemicals and coatings.

YH-A50 granule packaging machine

The YH-A50 granule packaging machine adopts high-speed sampling processing instruments and digital frequency conversion technology, featuring automatic setting of control parameters and automatic correction of drop. It can adapt to the characteristics of different packaging materials, operate continuously, and is simple and flexible to operate.

YH-A50S granule packaging machine

The two weighing buckets of the YH-A50S granule packaging machine can work alternately and simultaneously, with a larger weighing range, higher speed and more accurate measurement accuracy. The operation is simple and easy to understand, and it is suitable for the simultaneous mixing and packaging of two or more materials.

YH-AUTO fully automatic packaging machine

The YH-AUTO fully automatic packaging machine will be designed, manufactured, installed, debugged, tested strictly in accordance with the technical performance and other relevant requirements of Party A until the system operates normally. The system continuously and automatically completes the entire production process of small packages of organic materials, including automatic weighing, automatic bagging, automatic filling, and automatic edge folding and sealing.

显示 1-18 个结果(共 38 个结果)