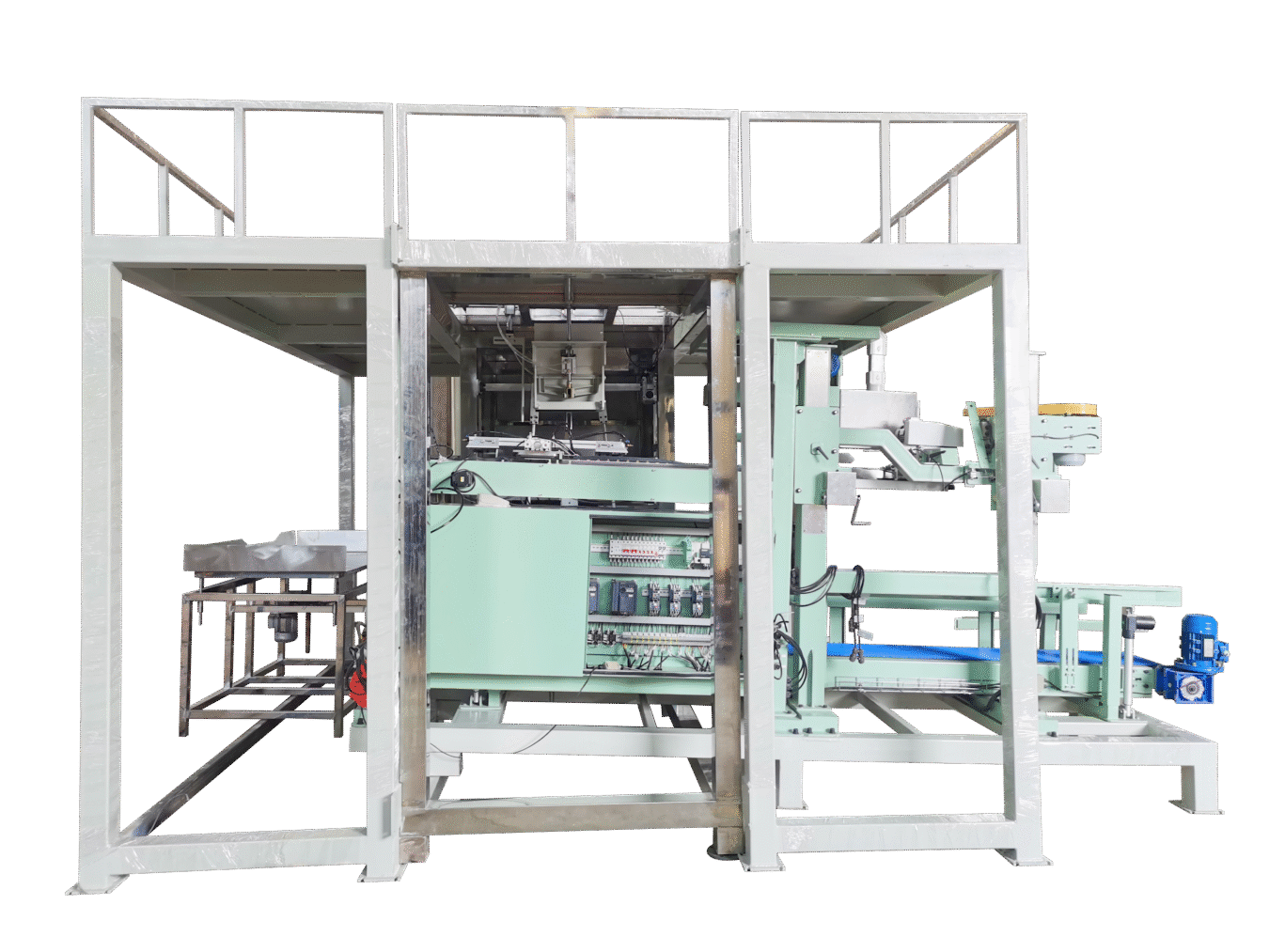

Granule packaging machines are driving transformative progress across food, pharmaceutical, and chemical sectors by combining precision engineering with smart automation. Below, we explore how these systems elevate production standards and catalyze industrial evolution.

4 Strategic Advancements Redefining Granule Packaging

1. Intelligent Control Systems

- HMI interfaces: Touchscreen panels simplify parameter adjustments (e.g., 0.5–50 lb/0.2–22.7 kg ranges) with <5-minute setup times.

- Adaptive algorithms: AI compensates for material density variations (±0.3% weight accuracy).

- Case example: A pet food manufacturer reduced giveaway costs by 18% using real-time fill weight optimization.

2. High-Speed Precision Engineering

- Oscillating fill technology:

- Processes 80–150 bags/hour (vs. 30–50 manually).

- Laser-cut sealing jaws ensure 99.9% hermetic integrity at 300–450°F (149–232°C).

- Hygienic design: CIP (Clean-in-Place) compatibility meets FDA 21 CFR Part 117 standards.

3. Cross-Industry Adaptability

| Industry | Key Requirements | Machine Modifications |

|---|---|---|

| Pharmaceuticals | GMP compliance, nitrogen flushing | ATEX-certified dust containment |

| Specialty chemicals | Explosion-proof construction | Hastelloy augers for corrosive powders |

| Premium teas | Aroma preservation | Oxygen-barrier film sealing |

Market expansion: 65% of manufacturers now serve ≥3 industries vs. 35% a decade ago.

4. Sustainability Integration

- Material efficiency: AI-guided film cutting reduces waste by 15–20%.

- Energy recovery: Regenerative drives reclaim 18–22% of braking energy.

- Circular economy: Compatible with 90%+ biodegradable/compostable films.

Growth Drivers & Market Outlook

- Demand surge: 5–7% CAGR projected through 2030, fueled by:

- E-commerce packaging needs

- Pharma serialization mandates

- Food safety regulations

- Regional hotspots:

- Asia-Pacific: 45% market share due to agrochemical demand

- North America: Premiumization in nutraceuticals

Chinese Engineering Excellence

- Cost leadership: 30–40% savings vs. EU/US machines without compromising ISO 9001 quality.

- Rapid customization: Modify hoppers, augers, and seals in 2–4 weeks.

- Smart maintenance: QR code-linked manuals enable 50% faster repairs (Patent ZL2023XXXXXX).

Implementation Roadmap

- Phase 1: Deploy semi-automatic models ($45k–$85k) for SKU diversification.

- Phase 2: Integrate IoT for predictive maintenance (ROI <8 months).

- Phase 3: Adopt AI vision systems for 100% inline quality control.

Leave a Comment

Your email address will not be published. Required fields are marked *