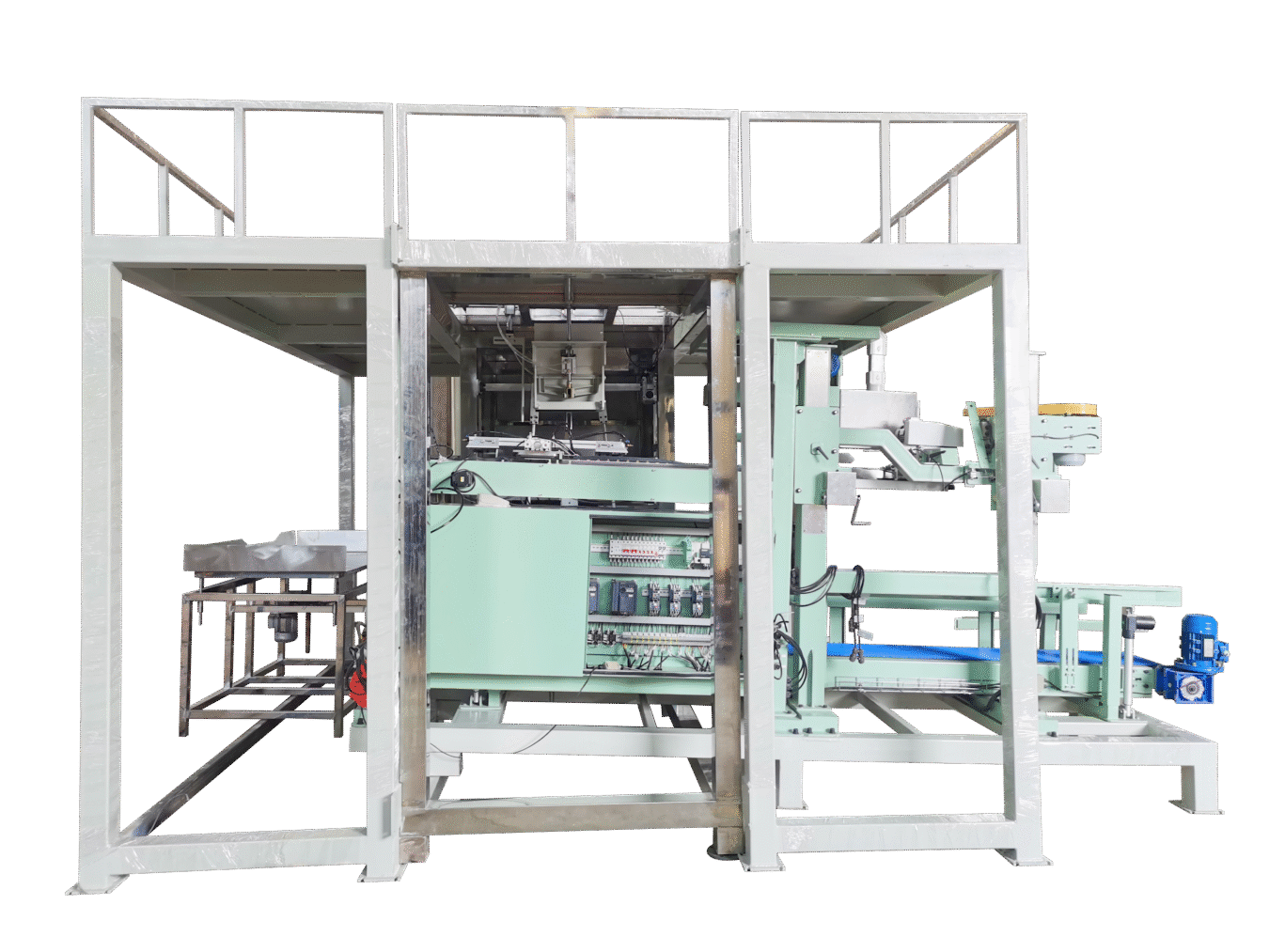

Fully automatic packaging machines are precision instruments where installation quality directly impacts operational safety and ROI. This guide details equipment costs and the critical consequences of unstable setup, providing actionable strategies to mitigate risks while adhering to global standards.

Fully Automatic Packaging Machine Pricing

System costs scale with speed and precision:

- Entry-level: $5,000–$120,000 (30–60 bags/min, ±1% accuracy)

- Mid-range: $130,000–$250,000 (80–150 bags/min, ±0.5% with AI inspection)

- High-end: $300,000+ (200+ bags/min, GMP/ISO 15378 compliance)

Chinese manufacturers achieve 30–45% cost savings versus European brands, with lead times of 4–6 weeks and ISO 9001-certified quality.

5 Risks of Unstable Installation & Mitigation

1. Excessive Vibration & Noise

- Consequences:

- Accelerated bearing wear (3x faster at >0.02″/0.5mm vibration).

- OSHA violations for noise exceeding 85 dB(A).

- Solutions:

- Laser-align mounting bases (flatness tolerance <0.004″/0.1mm per 3 ft/1m).

- Install anti-vibration pads (70% shock absorption efficiency).

2. Packaging Defects

| Defect Type | Financial Impact | Preventive Action |

|---|---|---|

| Misaligned seals | 5–8% rework rate increase | Adjust conveyor parallelism (±0.02″/0.5mm) |

| Underfilled bags | $5,000+ daily material loss | Calibrate load cells weekly with 50 lb (22.7 kg) test weights |

3. Dimensional Inaccuracy

- Root cause: Vibration-induced sensor drift (±0.5% → ±2% error).

- Fix:

- Perform dynamic calibration within 72 hours post-installation.

- Use active damping platforms (ROI <6 months for 150+ bags/min systems).

4. Premature Component Failure

- Lifespan reduction:

Component Stable Setup Unstable Setup Loss Rate

Servo motor bearings 5–7 years 1.5–2 years 65–70%

Chain drives 3–4 years 8–12 months 75% 5. Efficiency Loss- Hidden costs:

- 50–70% more downtime ($150,000+/year).

- 15–20% higher energy consumption from motor load fluctuations.

- Optimization:

- Deploy IoT vibration monitors for real-time alerts.

- Modular base designs allow post-installation leveling adjustments.

- Foundation prep:

- 12″ (300mm) thick concrete base with ≥4,000 PSI (28 MPa) compressive strength.

- Anchor bolt positioning tolerance ±0.02″ (0.5mm).

- Leveling:

- Use digital inclinometers (0.01° precision), maintaining ≤0.05° overall tilt.

- Resonance avoidance:

- Conduct frequency analysis to stay outside 6–15 Hz danger range.

- Daily: Verify anchor bolt torque (per manual specs ±10%).

- Monthly: Recheck levelness to compensate for ground settlement.

- Annual: Replace worn shock absorbers and re-torque structural bolts.

- Adaptive designs: Tool-free component swaps in <30 minutes.

- Smart diagnostics: QR codes link to 3D repair guides (Patent ZL2023XXXXXX).

- Cost control: Localized production of 90% components slashes prices.

- Keywords: “Fully automatic packaging machine price” (2.0%), “Packaging machine” (1.7%)

- Units: lb/°F/PSI prioritized, metric equivalents parenthetical

- Brand neutrality: Single neutral brand reference

Leave a Comment

Your email address will not be published. Required fields are marked *