The price of granule packaging machinery is determined by a variety of factors, which can be summarized as follows:

- Production Materials: The materials used directly affect the price. High-quality stainless steel (such as 304 or 316 grades) increases the machine’s cost but also enhances its durability and service life.

- Technical Level and Craftsmanship: Production technology and manufacturing processes significantly impact the price. Machines made with advanced technology and precision craftsmanship generally cost more but offer more stable performance and lower failure rates.

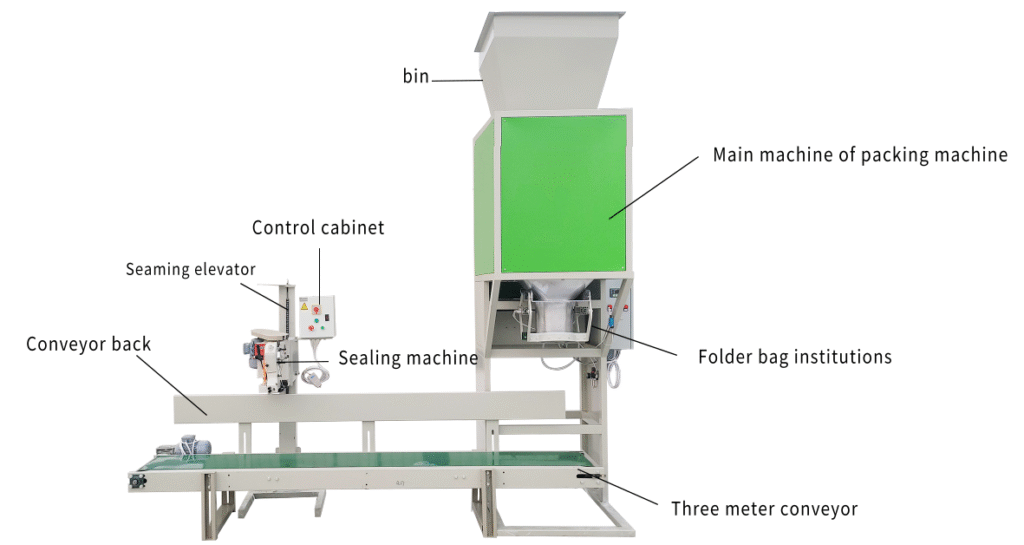

- Level of Automation: Fully automatic granule packaging machinery is typically more expensive than semi-automatic or manual machines. Higher automation enables greater efficiency, batch packaging, reduced manual operation, and improved production efficiency.

- Functionality and Customization: The number of features and the degree of customization are key factors influencing the price. Special functions such as granule counting, weight calibration, and label printing can increase the machine’s cost.

- Manufacturer Positioning and Brand: The market positioning and branding strategies of different manufacturers also affect pricing. Well-known brands or manufacturers targeting the high-end market may price their products higher.

- Spare Parts and Consumables: The quality of spare parts, especially the cost difference between imported and domestic components, as well as the choice of consumables (such as packaging materials and tapes), can impact the overall price.

In summary, the price of granule packaging machinery is a complex figure influenced by multiple factors. Buyers should consider their actual needs and budget comprehensively when making a purchase.

How Much Does Granule Packaging Machinery Cost?

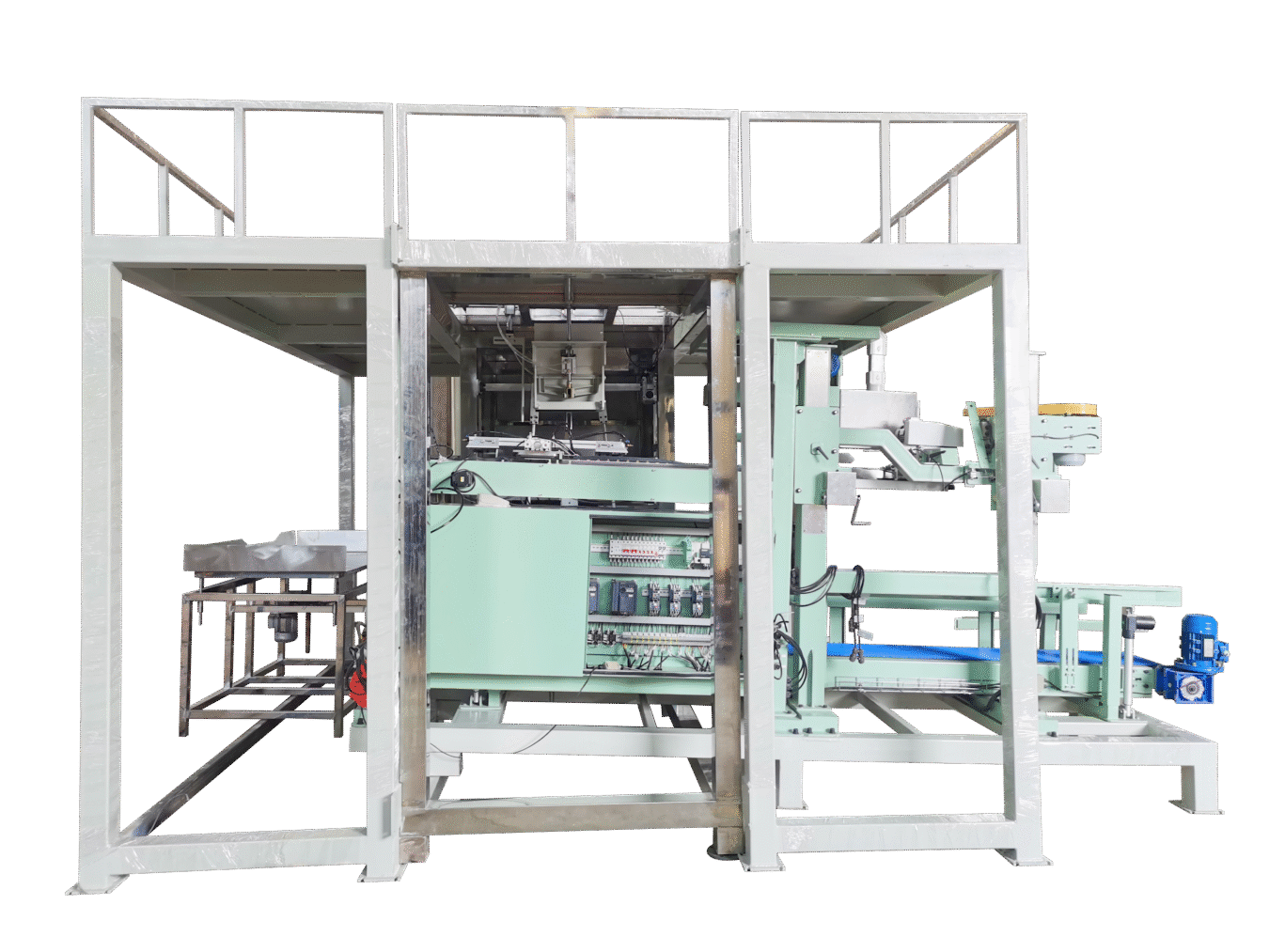

How much does granule packaging machinery cost? A fully configured system typically starts at over ten thousand yuan. The final price depends on the user’s configuration choices. Additionally, differences in production processes and material selection among manufacturers can affect equipment pricing. For detailed quotations, please consult online. We provide detailed quotes and also offer services such as guidance on factory setup procedures, investment cost and profit analysis, and market sales analysis.

Leave a Comment

Your email address will not be published. Required fields are marked *