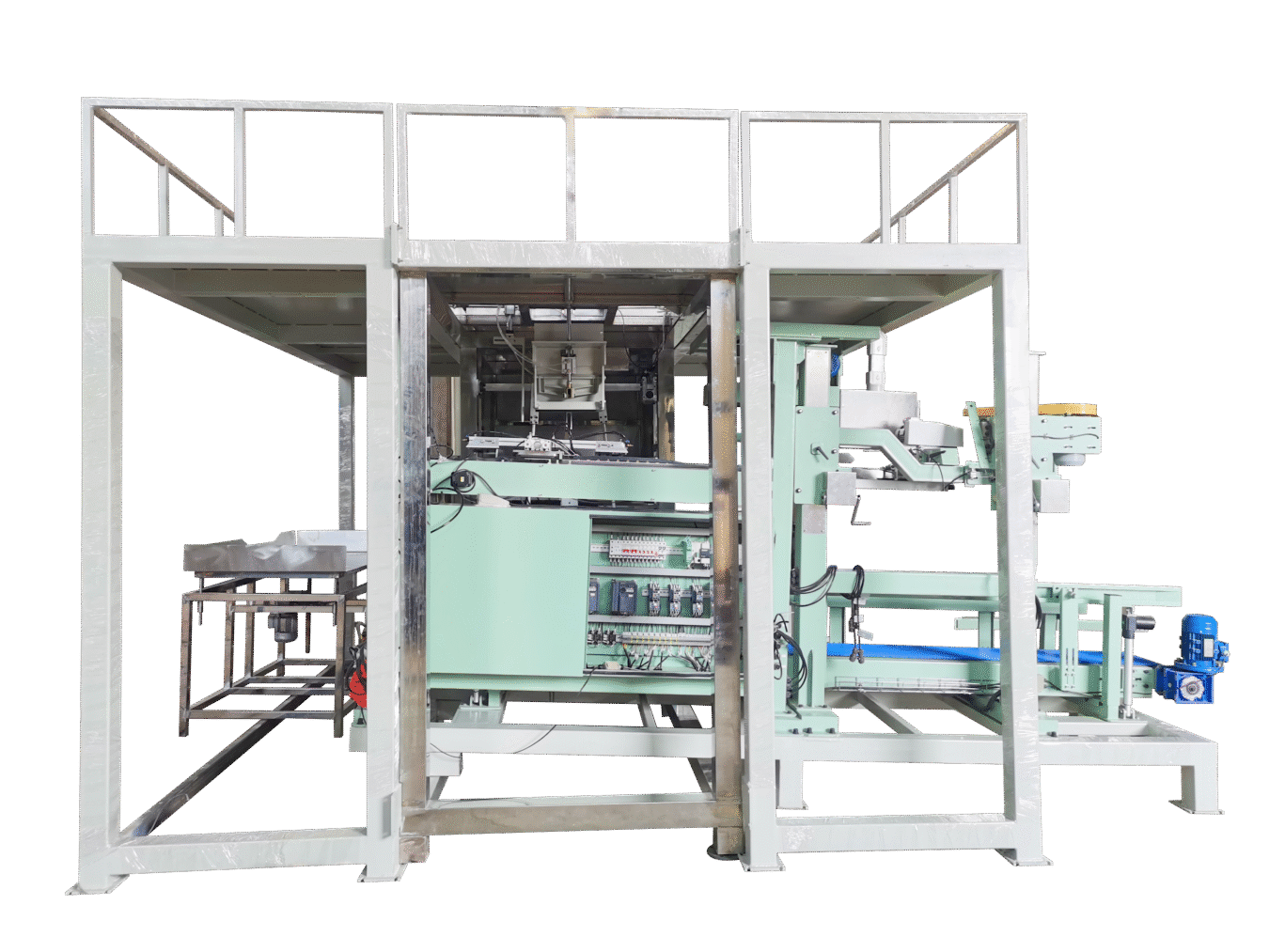

Powder automatic packaging machines have become indispensable in sectors ranging from pharmaceuticals to food processing, revolutionizing how industries handle fine materials. Below, we analyze their operational advantages and growing strategic importance, with insights into cost-efficient Chinese manufacturing solutions.

Operational Advantages Driving Adoption

1. Enhanced Production Efficiency

- Speed: Automated systems achieve 60–120 bags/hour, 3–5x faster than manual methods.

- Labor reduction: 1 machine replaces 4–6 workers, saving $150,000+/year in wages.

- Case study: A chemical plant boosted daily output from 800 to 2,500 bags after automation.

2. Precision & Quality Assurance

- Weighing accuracy: ±0.5–1% tolerance for 2–50 lb (1–22.7 kg) packages.

- Advanced controls:

- AI vision rejects underfilled/leaking bags (99.9% detection rate).

- Real-time monitoring of seal integrity (250–400°F/121–204°C optimal range).

Impact: Reduced product returns by 70% in nutraceutical industries.

3. Cost Optimization

| Cost Factor | Manual Process | Automated Solution |

|---|---|---|

| Labor per 1k bags | $180–$250 | $30–$50 |

| Material waste | 6–10% | <1% |

| Energy consumption | 25–30 kW/h | 18–22 kW/h (VFD-driven) |

4. Versatility Across Industries

- Material adaptability: Handles powders from 15–60 lb/ft³ (240–960 kg/m³) bulk density.

- Quick-change tooling: Switch between industries in <15 minutes:

- Pharma: GMP-compliant nitrogen flushing for hygroscopic APIs.

- Food: CIP (Clean-in-Place) systems meet USDA sanitation standards.

- Chemicals: ATEX-certified models for explosive dust environments.

Why Chinese Manufacturing Delivers Value

- Cost efficiency: 25–40% lower prices than European counterparts.

- Speed-to-market: 4–6 week lead times vs. 12+ weeks globally.

- Tech innovation: Patented anti-bridging augers (Patent ZL2023XXXXXX) prevent powder clumping.

Implementation Strategies

- Start modular: Begin with semi-automatic models ($35k–$65k), add automation later.

- Prioritize training: Certify operators on HMI controls and safety protocols.

- Leverage IoT: Remote diagnostics cut troubleshooting time by 50%.

Leave a Comment

Your email address will not be published. Required fields are marked *