BB fertilizer production line

The BB fertilizer production line is a kind of equipment that takes chicken and pig manure as the main raw materials, adds a certain amount of nitrogen fertilizer, phosphorus fertilizer, potassium fertilizer, magnesium sulfate, ferrous sulfate and other substances, and ferments rice bran, yeast, soybean meal and sugar for a certain period of time as biological bacteria. Under the action of sulfuric acid, it is mixed and fermented to produce biological fertilizer

Compound fertilizer production line

The process flow of a compound fertilizer production line can generally be divided into: raw material batching, raw material mixing, raw material granulation, granule drying, granule cooling, granule classification, finished product coating, and finally finished product packaging.

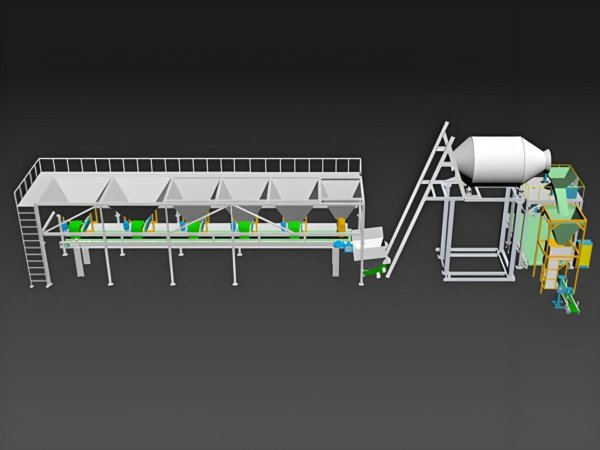

De-icing agent production line

The deicing agent production line includes: batching system, conveyor, batching system frame, drum mixer, ton bag machine, quantitative packaging machine, silo and other equipment.

Organic fertilizer production line

The products produced by the organic fertilizer production line are made from fresh chicken and pig manure as raw materials, without any chemical components. Chickens and pigs have poor digestive capabilities and can only consume 25% of the nutrients in the feed, while the remaining 75% of the nutrients in the feed are excreted with the manure. As a result, the dry finished products contain nitrogen, phosphorus, potassium, organic matter, amino acids, proteins and other components.

Water-soluble fertilizer production line

The water-soluble fertilizer production line has a complete set of strict operation procedures and systematic management methods. The use of equipment and technology has increased work efficiency by 10% to 25% compared with products in the same industry. The quality of the finished products is matched with multiple production processes and formulas, all reaching or even exceeding the prescribed standards.

显示所有 5 结果