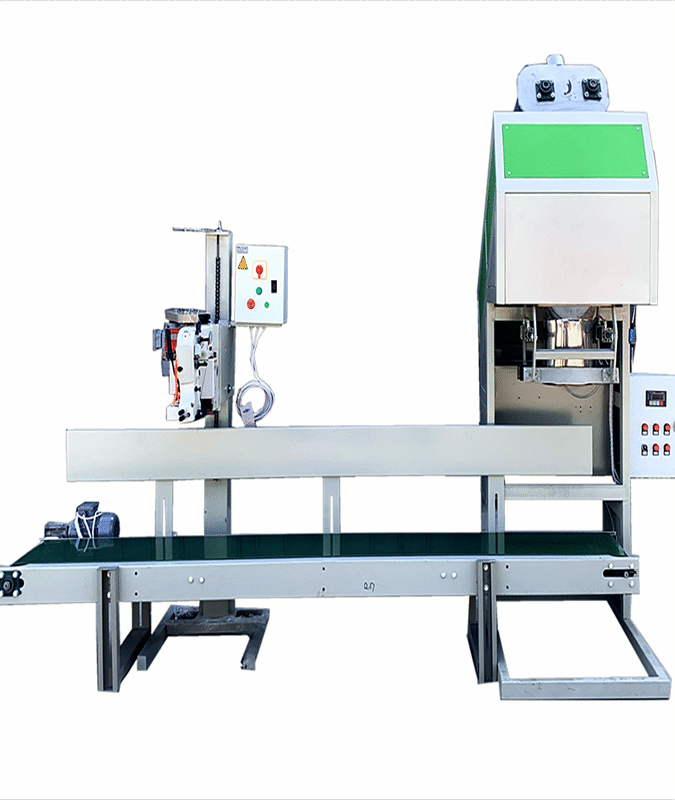

Description

Applicable materials:

Granular materials, powdered materials, and mixed materials. With its “fast, accurate and stable” features, it has become the choice for packaging in various industries

Functional features:

It integrates feeding, weighing, bag clamping, conveying and bag sewing. It is suitable for woven bags, gunny bags, paper bags, cloth bags and plastic belts, etc

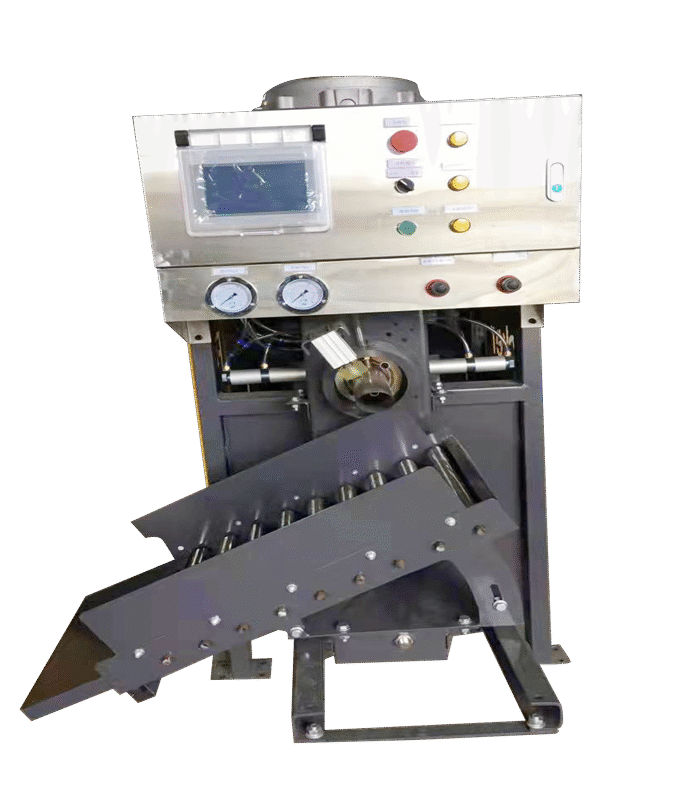

2. Material All parts in contact with materials are made of 304 stainless steel, which has a high resistance to pitting corrosion. It adopts pneumatic actuator, which is reliable in operation and simple to maintain

3. It adopts high-speed sampling processing instruments and digital frequency conversion technology, featuring automatic setting of control parameters and automatic correction of drop. It can adapt to the characteristics of different packaging materials, operate continuously, and is simple and flexible to operate.

4. It is equipped with RS-232C or RS485 communication interfaces, which can be networked with the upper computer. It has a complete exhaust system and good sealing performance. Double sealing prevents powder leakage and ensures the high purity of the product

5. The specially designed feeding and bucket-type metering mechanism increase the flow rate of materials, ensuring fast packaging speed and high packaging accuracy. Customization can be made according to customer requirements

6. It is widely applicable to the automatic quantitative packaging in the production and operation of industries such as grain, oil, feed, food, sugar, starch, flour, protein powder, fiber, bran, seed processing, chemical engineering, fertilizer, cement, warehousing, and ports. It has a wide quantitative range, high precision, and when used in conjunction with a conveyor seam machine with a height-adjustable table surface, it can be used for multiple purposes and has high efficiency.

There are no reviews yet.