Description

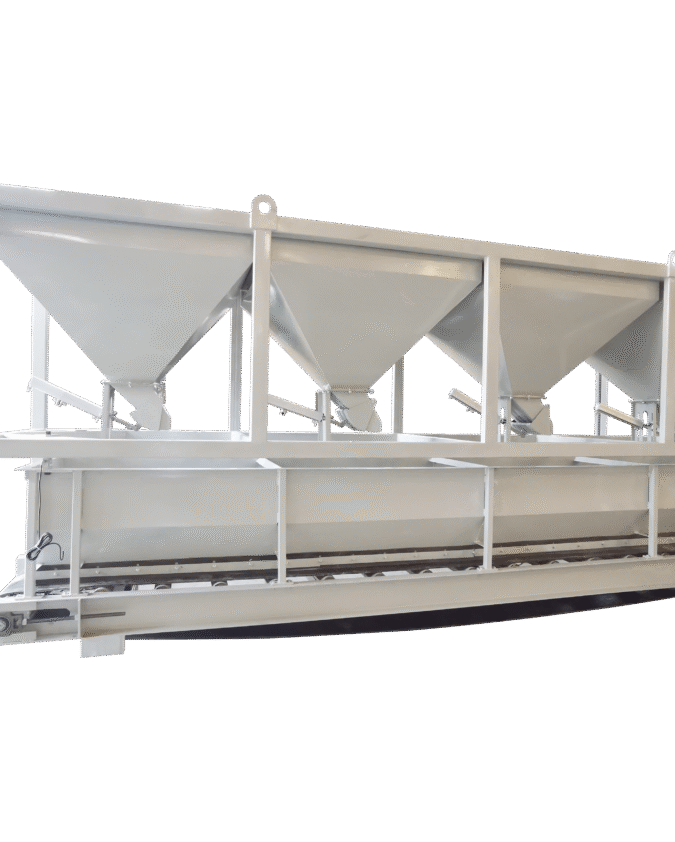

Finished product silo: Dimensions: 1800*1200*1000mm

Material: Stainless steel, carbon steel

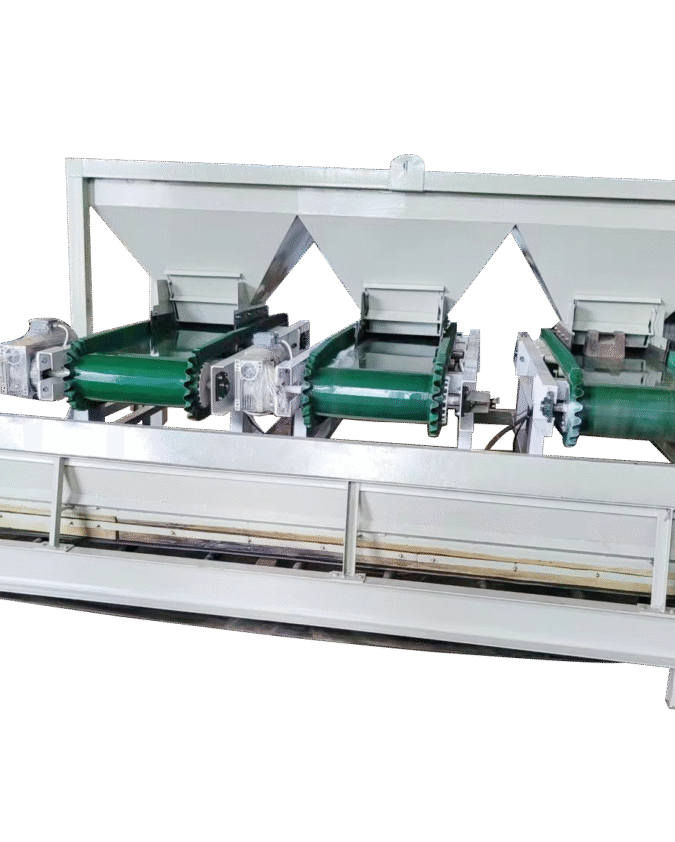

Feeding machines: They are divided into three types: bucket type, belt type and screw type, with the actual material suitability as the standard.

Packaging scale: There are two types, granular and powdered

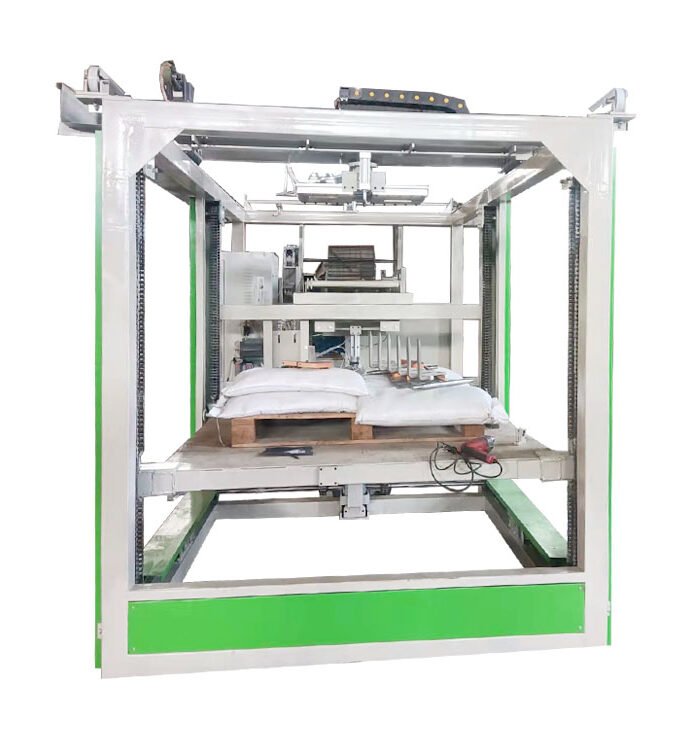

Automatic bag feeding machine: Bag storage 100-300(sound and light alarm when there are no bags)+ bag suction (the bags should be covered with film inside, the kind that is not breathable, to prevent air leakage when the suction cup sucks the bags and prevent them from not being able to hold tightly)+ bag putting

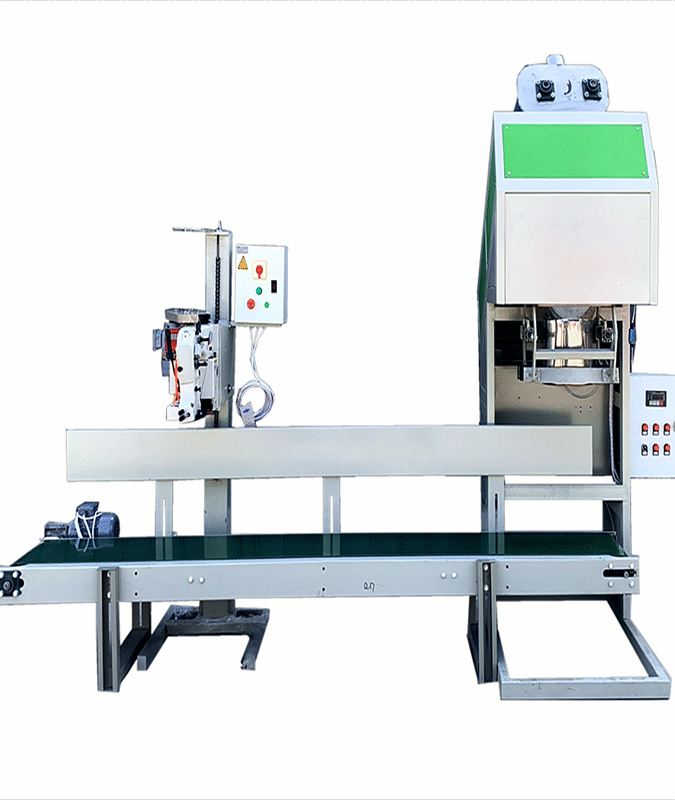

Automatic bag sewing system: traction + shaping + folding edge + bag sewing + cutting line + coding (sewing label)(configured according to the packaging material)

Applicable packaging materials: woven bags, hard plastic bags, etc.

Performance advantages:

The YH-AUTO fully automatic packaging machine integrates automatic bagging, positioning, opening, bagging, weighing, labeling and coding, and sewing. It realizes unmanned operation of product packaging, thereby improving efficiency and reducing labor intensity.

2. The drive core is composed of a PLC programming control system, a servo power system and a pneumatic execution system. The automatic control from weighing to bagging and packaging is completed through a liquid crystal touch screen human-machine interface.

3. The setting and modification of packaging parameters can be easily accomplished through the touch screen. The touch screen can remember and store the packaging parameters of 10 different products. When changing the product, it can be recalled and used at any time without the need for reset.

4. According to the specific conditions of the customer’s materials and production volume, different feeding methods (such as vibrating, belt, and screw feeding) can be customized into single bucket, double bucket, and automatic quantitative combination scale packaging. The weighing hopper of the weighing machine adopts a closed load weighing hopper design, which can prevent material leakage and residual material jamming during weighing.

5. The YH-AUTO fully automatic packaging machine adopts optical fiber recognition signal transmission and has an encoder confirmation function, which ensures higher accuracy.

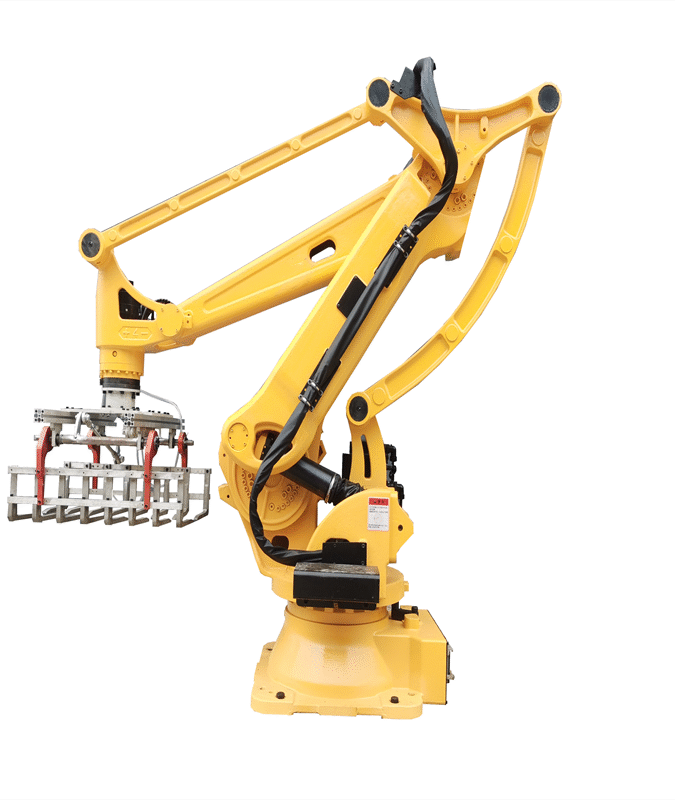

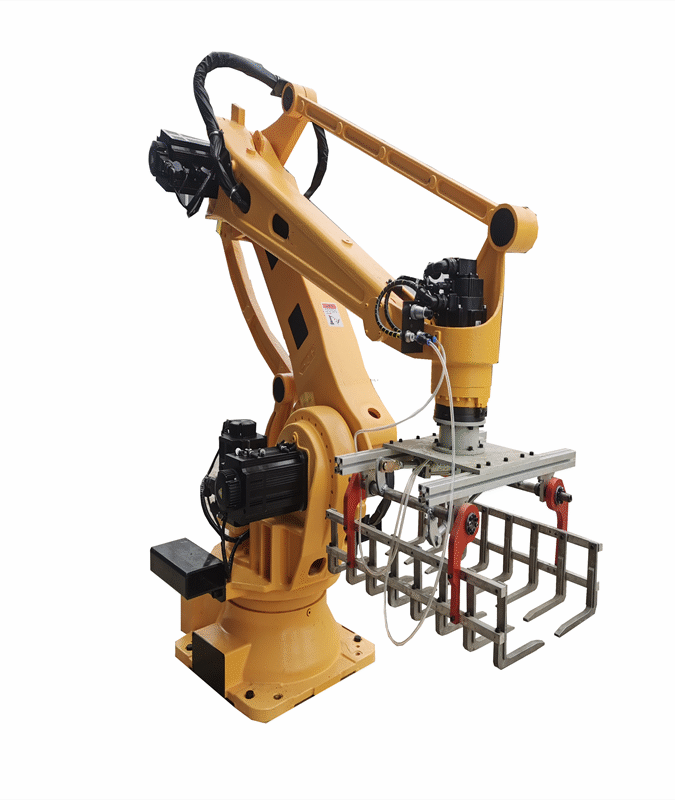

6. By equipping with palletizing robots, the integration of packaging and palletizing can be achieved, thereby enhancing production efficiency, improving the process flow, and reducing energy consumption.

There are no reviews yet.